Screen Printing Workshop Lesson Plan (60 Minutes, No Darkroom)

Jan 07,2026 | 4XTRON

How to Run a Screen Printing Workshop (No Darkroom): A 60-Minute Lesson Plan + Materials List

Workshops fail for one simple reason: traditional screen making has too many steps for beginners.

Your goal is not to teach everything.

Your goal is to help people leave with one successful print—and the confidence to do it again.

This guide is built for:

• schools & makerspaces

• pop-up workshops

• small studios running paid classes

• anyone who wants a repeatable, low-mess process

If you run workshops often, the biggest “easy win” is choosing a workflow that removes darkroom dependency and keeps results consistent.

Quick recommendation (most workshop-friendly path): start from a ready-to-print bundle and scale later.

The workshop format that actually works (and why)

One design. One color. One screen. One print per student.

Anything more becomes chaos.

Why this works:

• fewer variables = fewer failures

• students focus on hand feel (angle, pressure, speed)

• cleanup stays manageable

• you can run the same class repeatedly and improve it each time

Materials list (lean version for a 60-minute class)

You need:

• Prepared screen/stencil (enough for class size)

• One ink system (choose one and stick to it)

• One squeegee type (medium durometer is easiest)

• tape + paper towels + basic cleanup plan

• blank tote bags or paper (totes are forgiving; paper is fast)

• a simple drying plan

Optional but helpful:

• hinge clamps / a small manual press for stable registration

• a few “demo screens” that are guaranteed to work

Learn more

If you run workshops, the easiest win is a compact workflow that avoids darkroom setup.

The clean workflow: Digital screen making → print (workshop-ready)

Here’s the simplified process you can repeat in classes without a full darkroom.

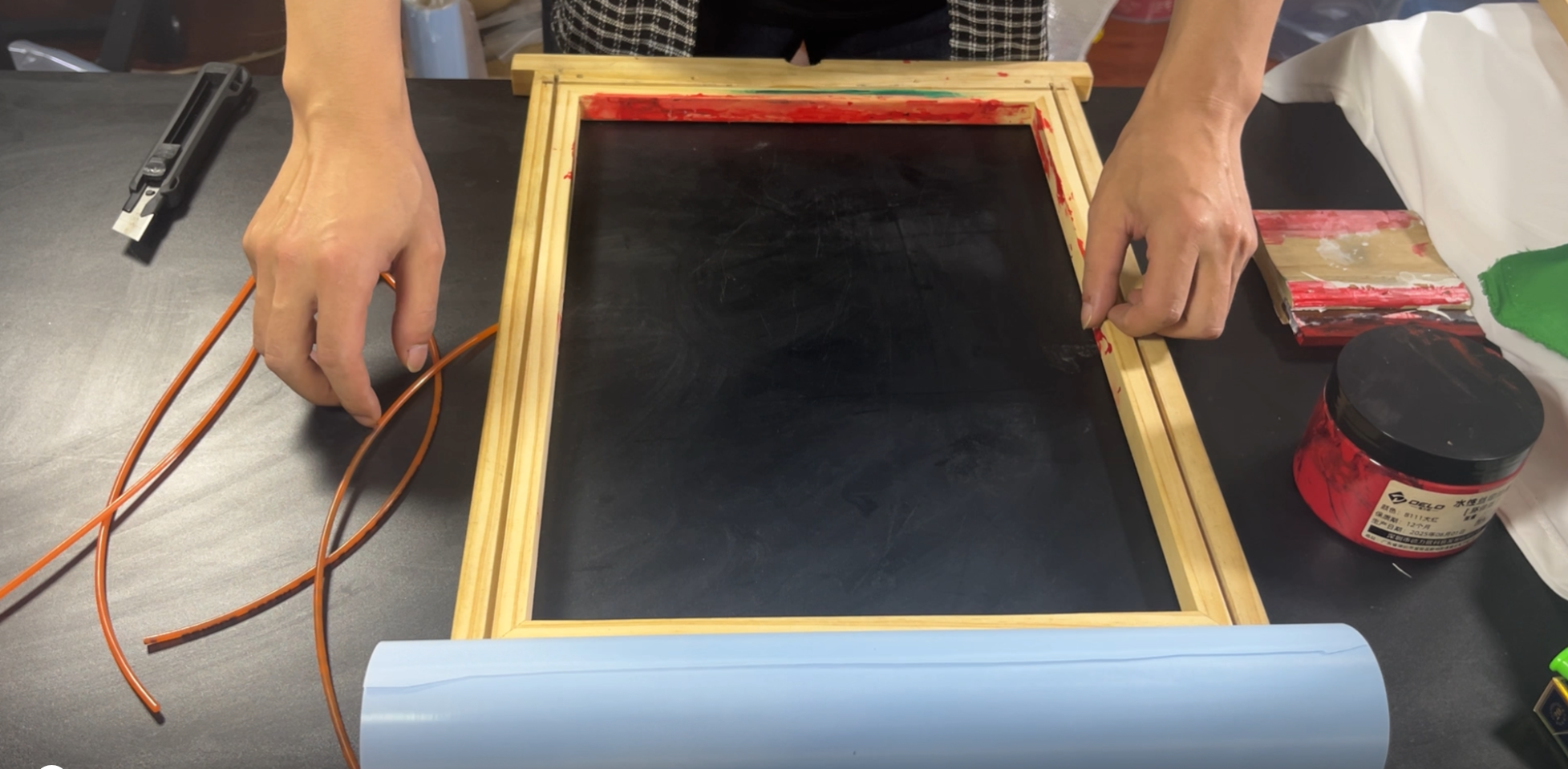

Step 1) Prep the screen for lamination

Step 2) Lay the stencil film smoothly

Placing stencil film evenly on the screen to prepare for digital screen making

Key rule: flat film = clean edges.

Wrinkles become print defects later.

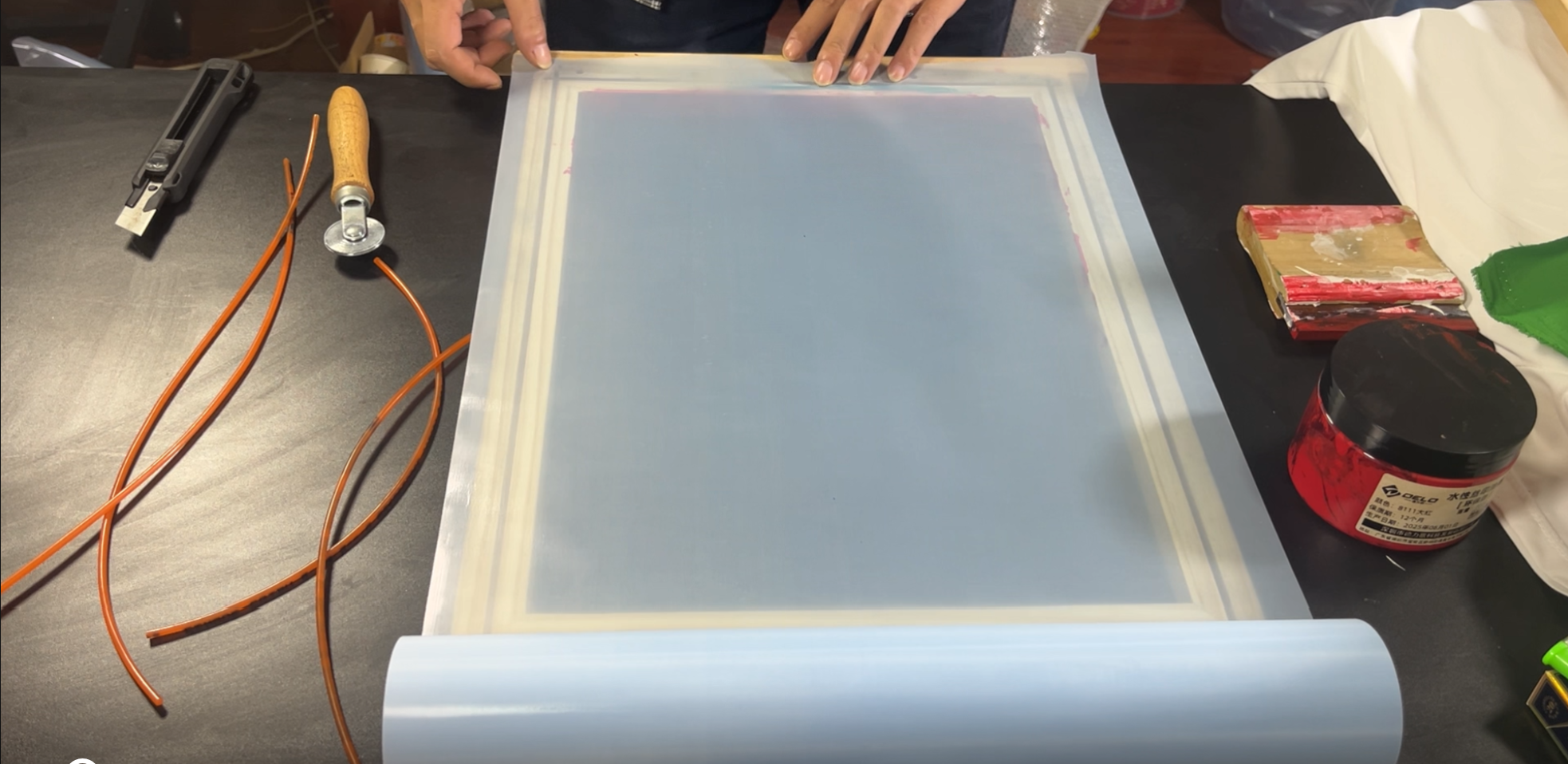

Step 3) Cover and protect the screen surface

Covering the screen with laminating sheet to keep the stencil film flat and clean

This keeps dust out and helps the film stay evenly pressed.

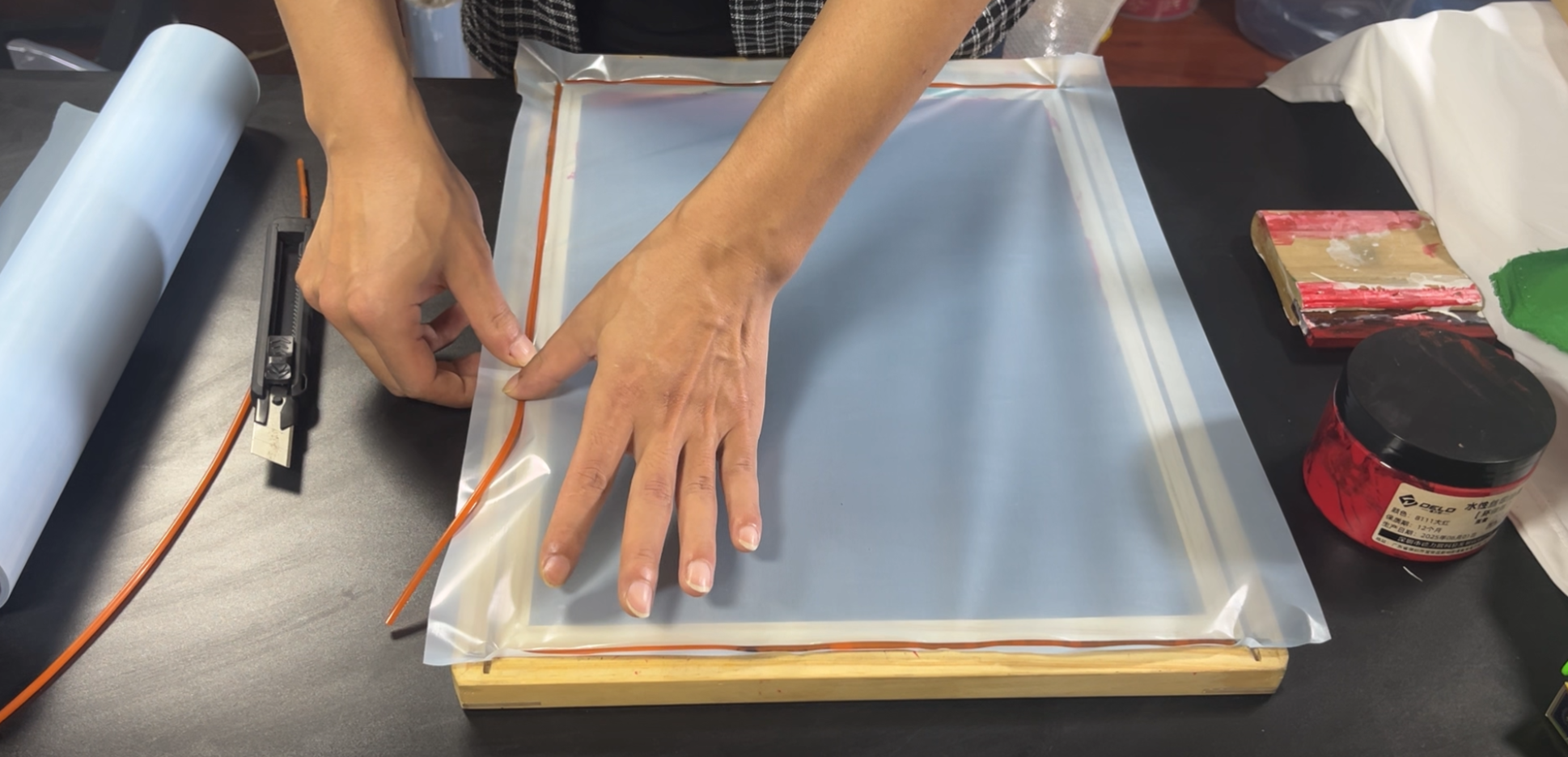

Step 4) Roll/press edges for a tight seal

Using a roller to press the sealing edge for a tight, wrinkle-free laminate

Your goal is a smooth, tight seal—no gaps on the edges.

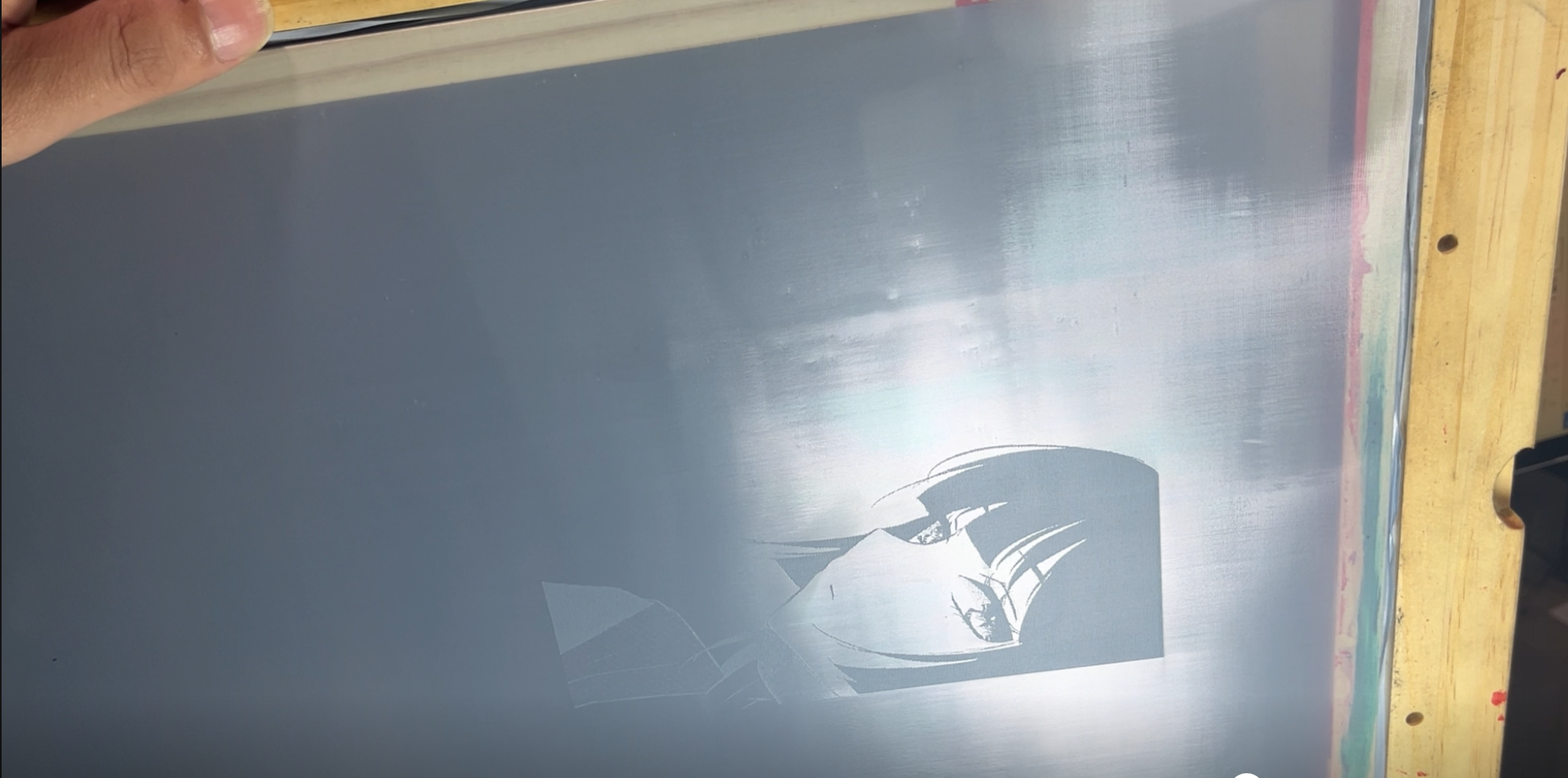

Step 5) Expose the design with PS5 (digital screen maker)

PS5 digital screen maker exposing the design onto the prepared screen

This is the “workshop unlock”: you can teach screen printing without building a darkroom workflow into the class.

If your goal is a classroom-friendly process without darkroom steps, see the PS5 digital screen maker.

Step 6) Confirm the stencil result before class starts

Finished screen after exposure, showing the artwork details ready for printing

Before students arrive, do a quick visual check:

• edges clean?

• small lines open?

• no obvious dust blobs?

If it looks good now, the printing part becomes easy.

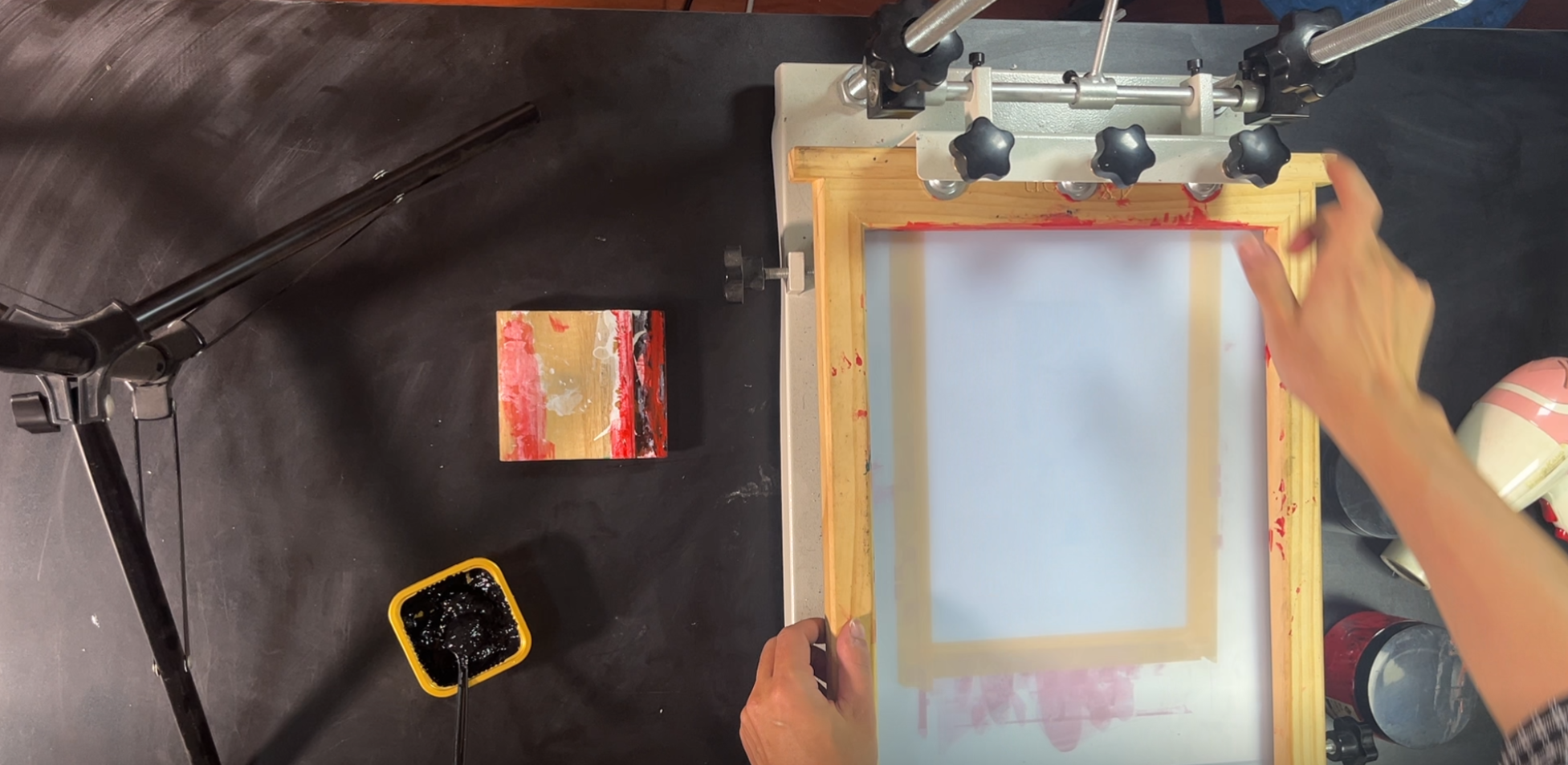

Step 7) Mount the finished screen on the press + align the frame (registration setup)

This step is about securing your finished screen on the press and dialing in alignment.

Adjust the screen frame position so your artwork lands exactly where you want it on the shirt/tote/paper.

Take 2 minutes here—good alignment saves you 20 minutes of rework later.

Step 8) Add ink (small amount first)

Adding ink to the screen before the first flood stroke

Beginner rule: start with less ink, add more if needed.

Step 9) Print with one steady pull

Pulling the squeegee to print a solid pass with consistent pressure and angle

What you teach students (the only 3 things that matter):

1. keep the angle consistent

2. steady pressure

3. don’t stop mid-stroke

Step 10) Show the finished result (confidence moment)

Final print result on paper after a clean single-color screen printing pass

This is where the workshop “click” happens: they see a clean print and realize it’s learnable.

.png?w=1536&h=1024&q=70)

.png?w=1536&h=1024)

1 comments