Screen Printing Starter Kit Checklist (2026)

Jan 06,2026 | 4XTRON

Screen Printing Starter Kit Checklist (2026): What You Need, What to Skip, and a 1-Day Setup Plan

If you’re starting screen printing, the internet will try to sell you everything. The truth: a clean, repeatable workflow beats a huge pile of tools.

This guide is written for:

home studios

small shops doing short runs

schools / workshops that need a predictable setup

And yes—if you want to skip darkrooms, messy coating, and chemical washout, you can build your workflow around a digital screen-making approach.

Quick start (recommended): If you want a ready-to-print setup with the least trial-and-error, start from a bundle and expand later.

→ screen printing starter bundles

1) The “Minimum Viable” screen printing setup (what you actually need)

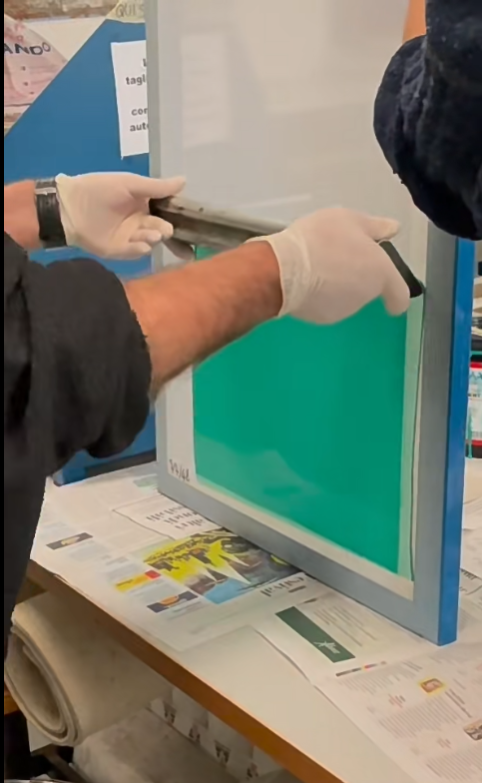

A. The screen / stencil

A screen (or pre-coated screen system) matched to your print style

A way to create the stencil (traditional exposure or digital)

B. Ink

Pick one ink system to learn first (plastisol OR water-based). Mixing systems early = frustration.

C. Squeegee

One medium-durometer squeegee is enough for learning.

The angle and pressure matter more than having 5 squeegees.

D. A stable printing surface

A flat table + simple registration marks beats complicated jigs.

E. Cleaning basics

Tape, paper towels, a scraper, and a safe cleanup routine.

2) What most beginners buy—and regret

You can skip these until you have real volume:

multiple emulsion types “just in case”

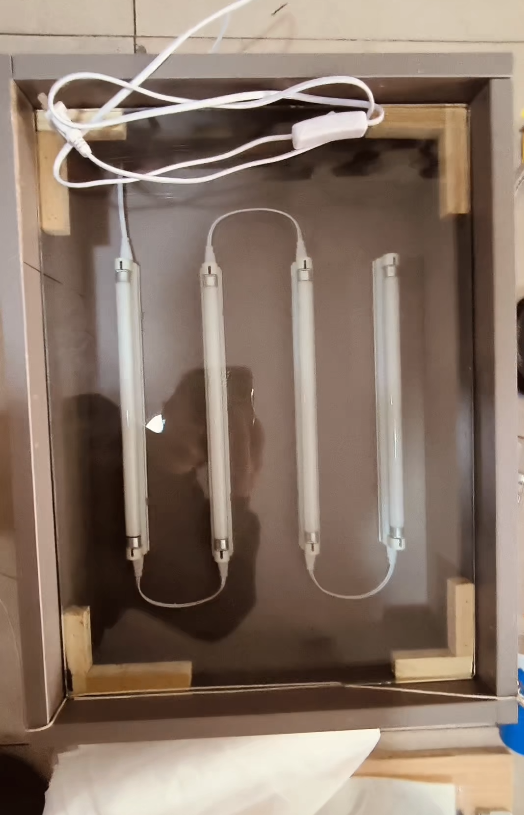

giant exposure units / washout booths (unless you’re committing to a full darkroom)

10 different inks “to experiment”

fancy platen systems before you can print consistently

Your goal for the first week is simple: repeatability.

3) Choose your first workflow: Traditional vs Digital (simple decision tree)

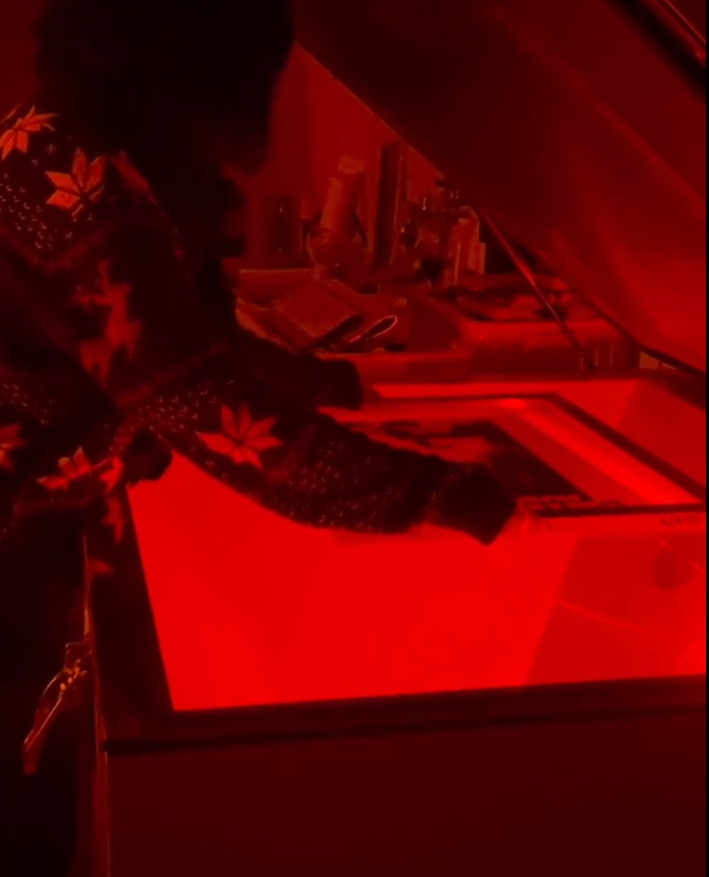

Pick Traditional Exposure if:

you already have a darkroom or shared facility

you want to learn classic screen-making as a craft

you’re okay with drying, washout, reclaiming cycles

Pick Digital Screen Making if:

you have limited space

you run workshops/classes

you want faster iteration and less mess

you need a predictable process for beginners

This isn’t “right vs wrong.” It’s about what your environment supports.

“If your goal is fast, classroom-friendly screen making without darkroom steps, see the PS5 A4 digital screen maker.”

→ Rapid screen printing plate making

“If your goal is fast, classroom-friendly screen making without darkroom steps, see the PS5 A4 digital screen maker.”

4) A 1-Day Setup Plan (so you don’t stall)

Hour 0–1: Pick your one product type

tote bags? tees? paper prints?

Choose ONE. Your screen + ink + mesh decisions depend on it.

Hour 1–2: Decide ink system

water-based: softer feel, but dries quickly on screen

plastisol: forgiving working time, needs curing

Hour 2–3: Build a simple registration

two marks + hinge clamps (or a simple alignment method)

start with 1-color prints first

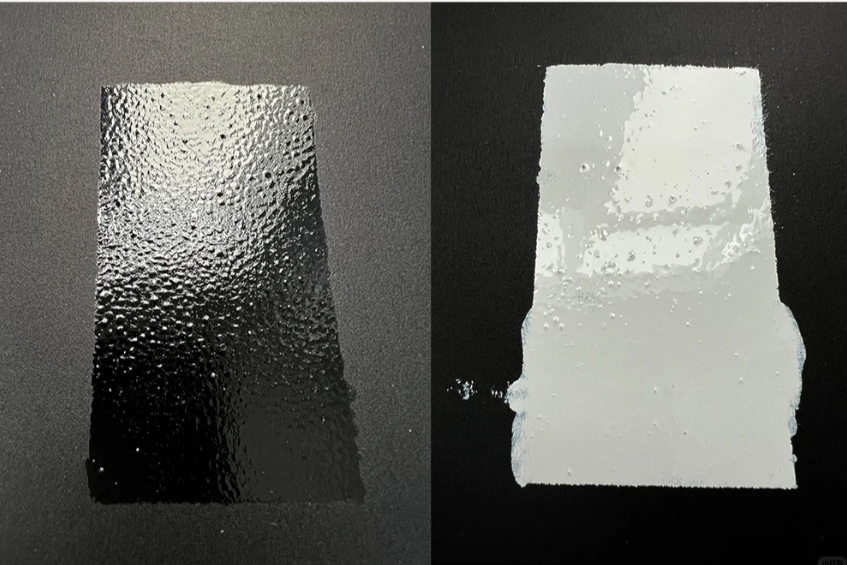

Hour 3–5: Run 10 test pulls

pull #1–3: you’ll be shaky

pull #4–10: you’ll learn the “feel” (pressure, angle, speed)

Hour 5–6: Document your settings

Write down:

ink type

mesh count (if applicable)

squeegee angle feel (low/medium/high)

off-contact (if you use it)

This is what turns “random luck” into a process.

5) Starter kits that make sense (two smart paths)

Write down:

ink type

mesh count (if applicable)

squeegee angle feel (low/medium/high)

off-contact (if you use it)

This is what turns “random luck” into a process.

Path A: “Fastest to consistent results” (recommended)

a complete package that’s already matched for beginners

→Quick Guide to Screen Printing

Path B: “Build piece-by-piece”

screen/stencil → one ink system → one squeegee → basic registration

This path is cheaper upfront but costs time.

6) FAQ

Do I need a darkroom?

Not always. It depends on your stencil-making method and space.

What’s the #1 beginner mistake?

Changing too many variables at once. Lock one workflow first.

Are you ready?

.png?w=1536&h=1024&q=70)

.png?w=1536&h=1024)