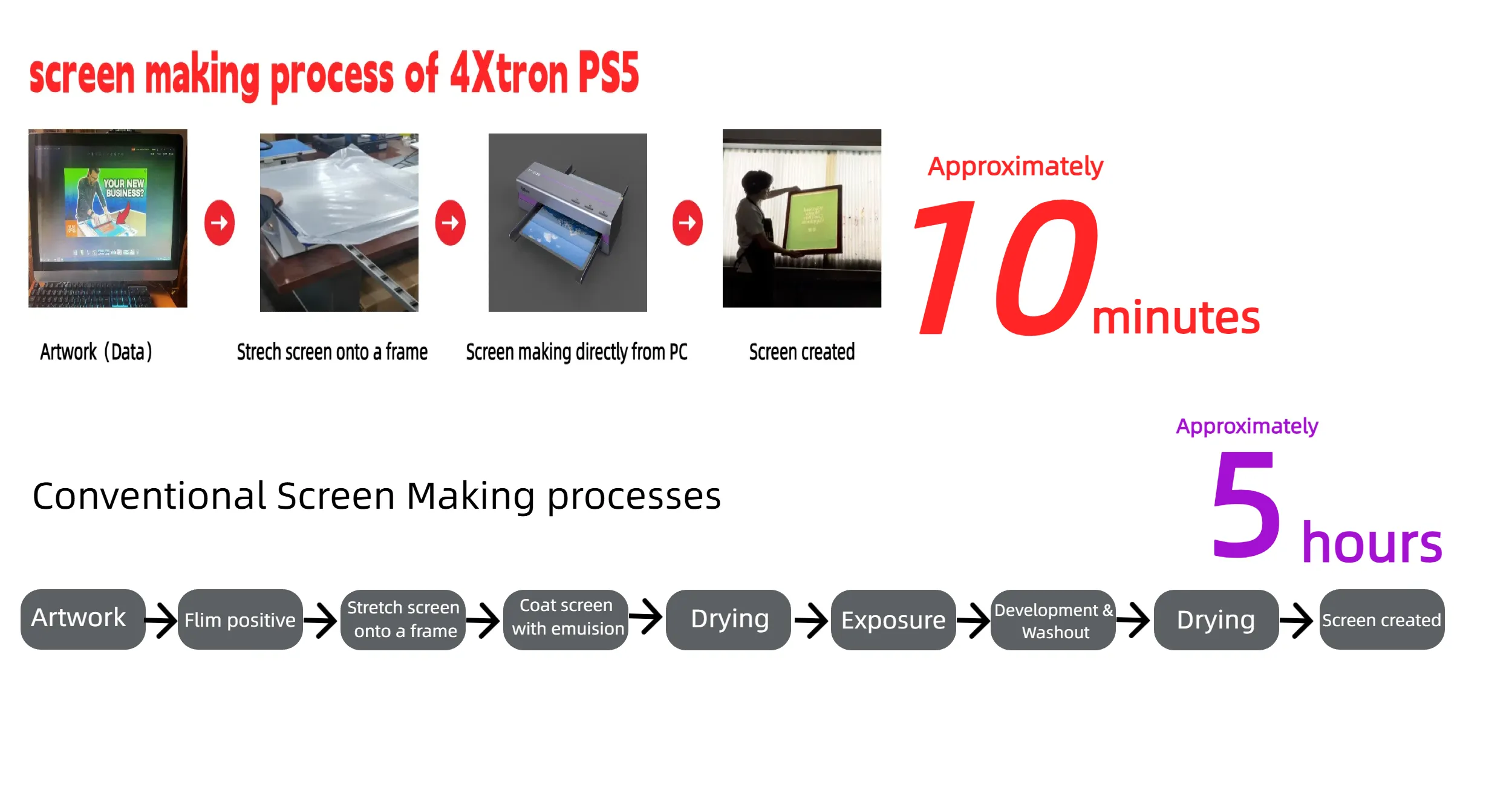

At the heart of the PS5 series lies the 4XTRON Dry Thermal CTS digital plate-making process, enabling precise, clean, and efficient stencil production. It works by accurately imaging a dedicated thermal screen master material—eliminating emulsion coating and washout water in the stencil-making step

Maximum efficiency, clean production. The 4XTRON Dry Thermal CTS workflow removes the need for emulsion coating, darkrooms, film positives, exposure units, and washout for stencil making. It’s a new era of screen printing: minimal setup, simplified workflow, and consistent thermal imaging results.

![]()

We have re-engineered the screen making process to deliver a seamless, streamlined workflow

One-button operation. Zero learning curve. Experience screen making that is as fast, simple, and intuitive as printing a document.

![]()

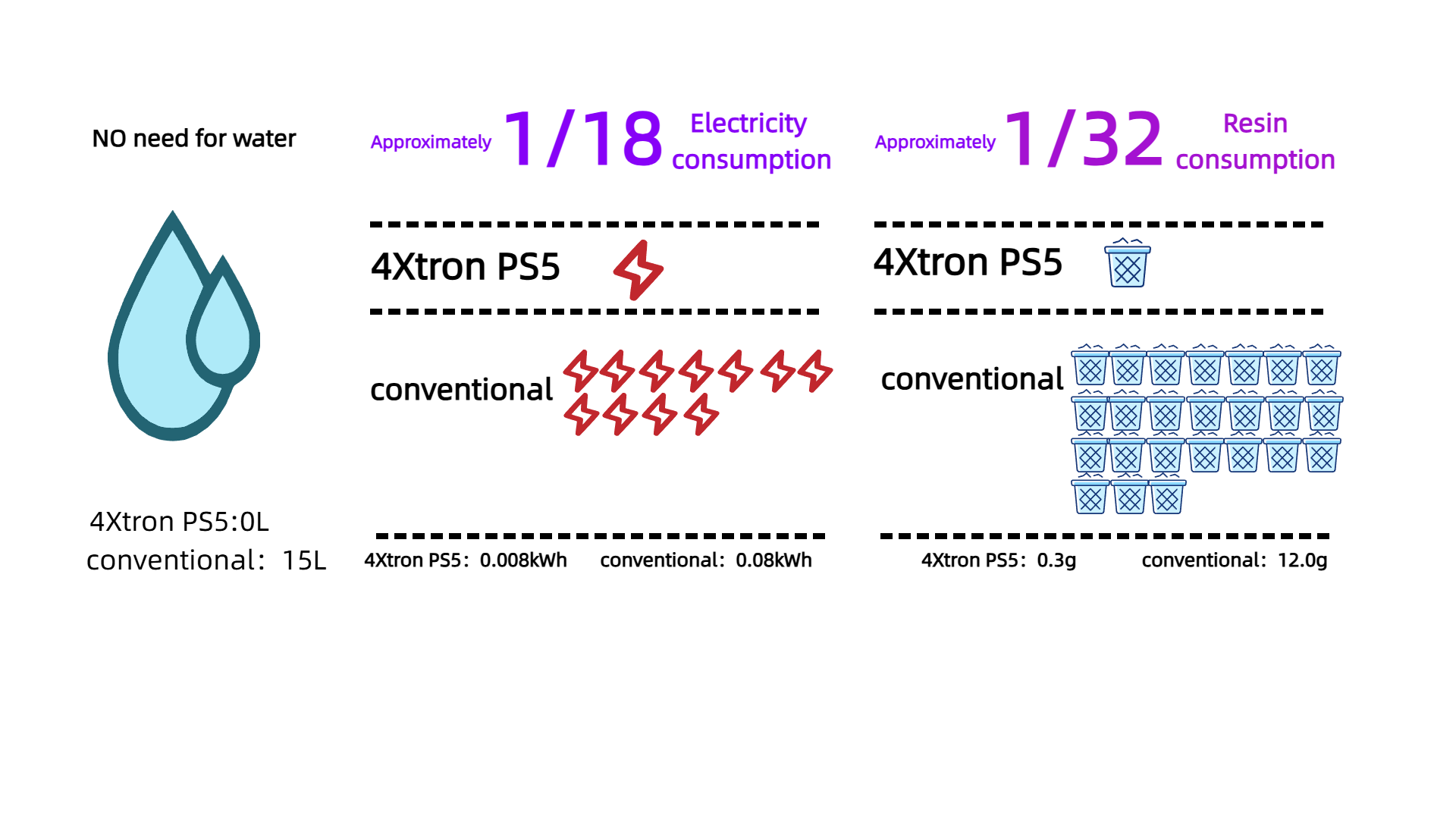

With zero liquid discharge and minimal power draw, it sets a new standard for eco-efficient production.

By design, it eliminates the entire resource-intensive chain—from emulsions and film positives to exposure, washout, and drying. This not only eradicates wastewater at the source but also cuts power consumption, offering substantial environmental and operational benefits.

![]()

Faster turnaround times accelerate your return on investment by cutting operational costs

It delivers savings on two critical fronts: exceptional speed that reduces labor expenses, and a space-efficient design that minimizes your facility's footprint—directly lowering overhead.

.png?w=1920&h=1080)

.png?w=1536&h=1024&q=70)

.png?w=1536&h=1024)